Nitra Combined Heat and Power Powerplant

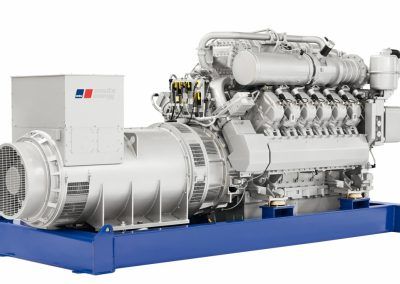

3,12 MW of electricity and 3,2 MW of heat will be produced from natural gas in KGE Nitra with two cogeneration units MP 2000 M-BCU

The core of the local powerplant, which supplies heat to Chrenová district of Nitra city, are two container cogeneration units Martin Power with MTU engines (part of Rolls Royce Power Systems group). The biggest curiosity of the whole powerplant is that cogeneration units use the combination of standard pipeline natural gas with low-LHV natural gas from local source. Cogeneration units work in parallel with the mains and in case of power outage are securely stopped with help of MP 30 P genset.

Important factor during projection and realization was total surpression of negative noise or emission influences to surrounding housing and environment, and brownfield revitalisation after collapsed mazut heating plant with high accent to architectonic value.